The explosion-proof wheeled inspection robot is mainly composed of the robot body, a wireless base station, an autonomous charging device, and a remote control station. It is widely used in Class II explosive environments. It can replace inspection personnel to conduct equipment and environmental inspections, reducing the labor intensity of inspection personnel, minimizing potential safety hazards during the inspection process, improving the quality of inspections, and maximizing the intrinsic safety level of petrochemical enterprises.

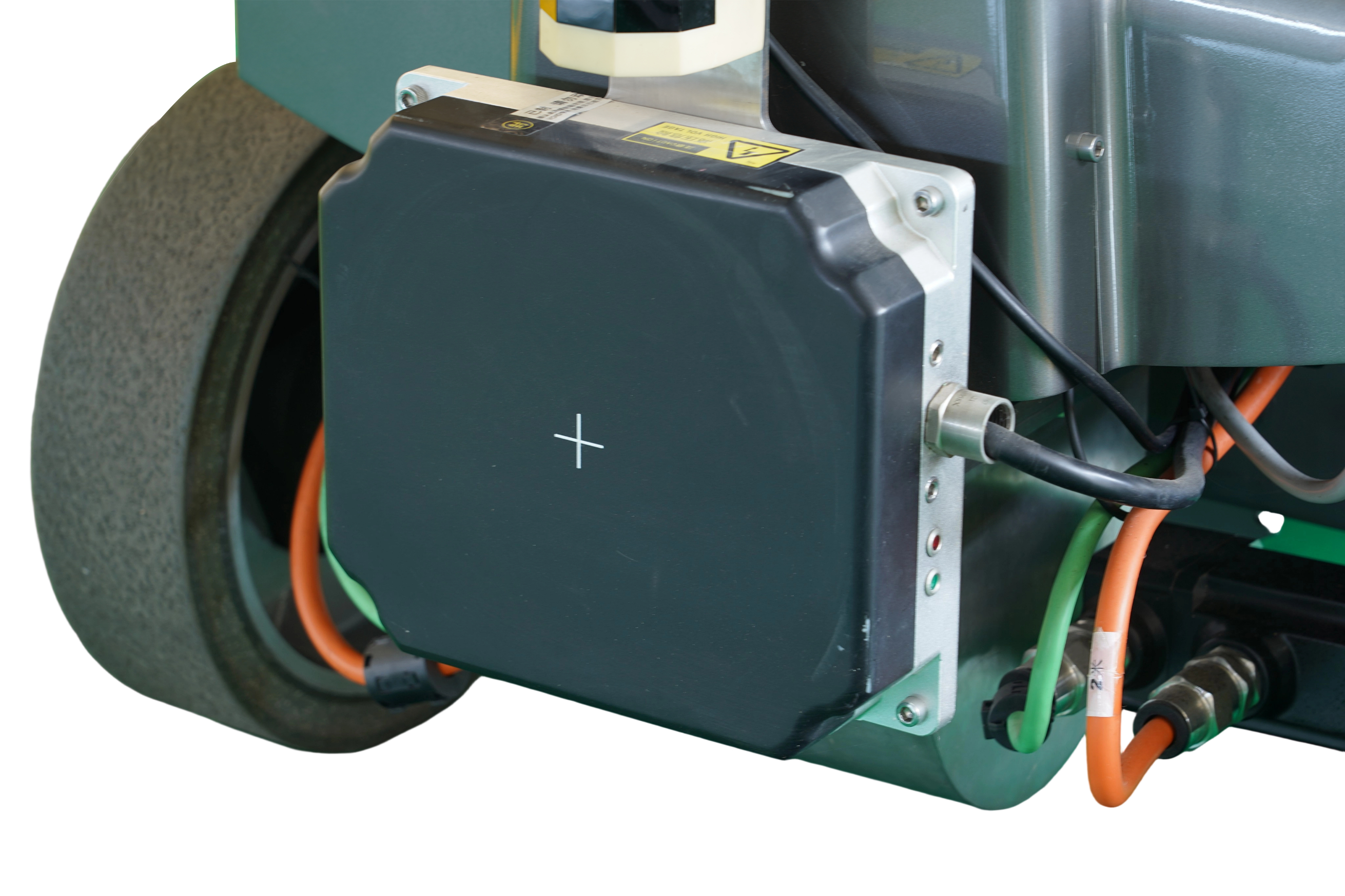

The explosion-proof modular wheel drive system is suitable for various ground environments, especially for extremely complex unstructured terrains such as gravel roads, shock-absorbing belt roads, etc;

Modular design, easy to expand, can be equipped with various detection sensors to meet different on-site needs;

Leakage Detection Function

Combining gas detection sensors with intelligent recognition algorithm detection technology, it can detect the leakage of flammable and explosive gases. Based on the integrated detection technology of image processing and deep learning, and aiming at the image features during liquid leakage, it can accurately detect the leakage in key areas of the oil pipeline.

Video Analysis Function

It can conduct intelligent analysis of on-site instruments, valves, and other equipment according to user requirements.

Audio Analysis Function

It can analyze and issue early warnings for the audio of on-site equipment such as cylinders, oil pumps, motors, and bearings according to user requirements.

Temperature Collection and Analysis Function

It can identify, analyze, and judge the temperature status of equipment, pipelines, and key components, and give timely alarms for abnormal high and low temperatures. By using the characteristics of temperature imaging, it can detect the temperature trends of key components at different time points.

Intelligent Anti-collision, Anti-fall, and Autonomous Obstacle Avoidance Functions

It adopts a highly stable infrared obstacle avoidance and anti-fall detection system. When encountering obstacles and downward steps, it will automatically stop and give an alarm to prevent damage to personnel and equipment caused by collisions.

Data Archiving and Historical Query Functions

The monitoring platform will automatically archive abnormal information found during the robot's inspection operations or its own faults, etc., and it can be viewed at any time.

Multi-angle Light Supplementation

It is equipped with light supplementation equipment to meet the lighting needs during the robot's inspection, ensuring the robot's application in all weather conditions and multiple scenarios.

Mobile Terminal Control Support

It provides an APP control terminal, enabling remote data presentation and remote control of the robot through mobile phone and tablet APPs. The more user-friendly platform software makes the operation simple and efficient.

A certain chemical plant

Application in a certain condensing plant

chemical plant

petrochemical industry