It is mainly applied in Class II explosive environments such as petrochemical enterprises, coking plants, refining plants, chemical plants, and gas transmission stations. It can replace manual inspections, which is of great significance for reducing labor intensity, lowering labor risks, and improving production safety.The inspection robot is equipped with multiple sensors to collect parameters such as on-site images, sounds, infrared thermal images, temperature, smoke, and concentrations of various gases in real time. The inspection robot has an intelligent recognition function. By using key intelligent perception technology algorithms, it can accurately determine the current operating status of equipment. Based on big data analysis and early warning technology, it can predict and give early warnings of equipment operation failures in advance, reducing the downtime due to failures.

Adopting advanced wireless mobile communication technology, with long communication distance and strong anti-interference ability, it can ensure real-time transmission of images and data while meeting explosion-proof requirements;

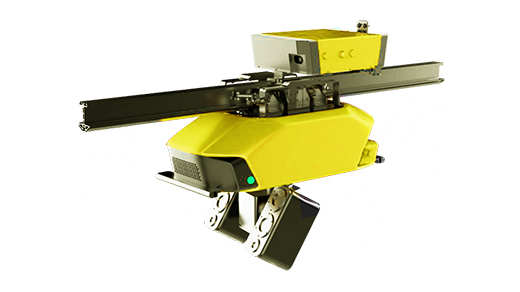

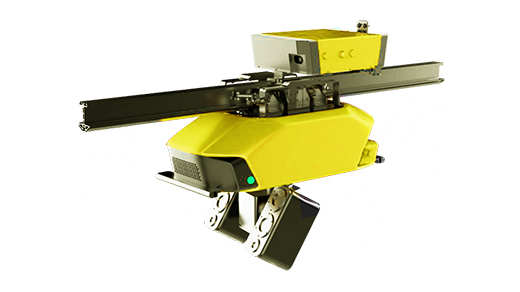

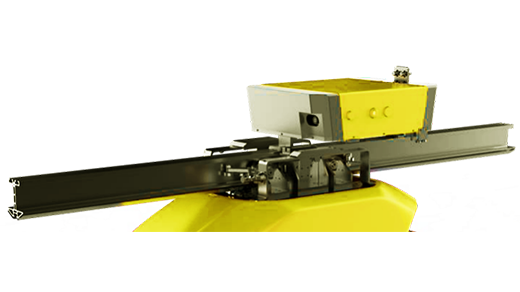

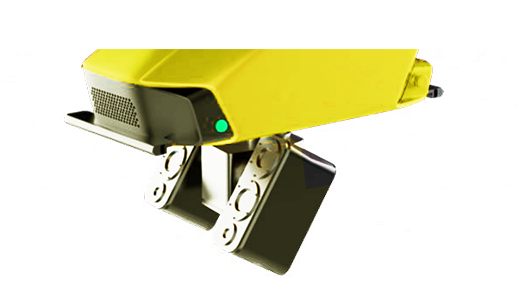

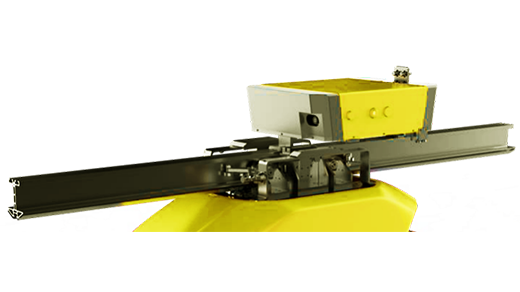

The robot adopts a suspended operation mode on the track, which does not occupy ground space and does not affect pedestrians;

Intelligent Recognition Function

It can intelligently recognize information such as the position of the valve stem, the status of the indicator light, and the instrument data on site.

Audio Analysis Function

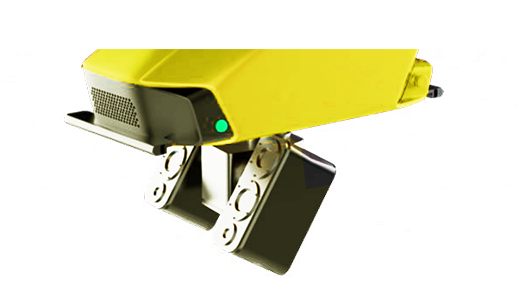

By collecting on-site sounds, it can intelligently analyze abnormal sounds and automatically give voice prompts when equipment failures are detected.

Environmental Detection Function

It can identify the content of toxic and harmful gases on site and timely determine the leakage situation of equipment.

Temperature Detection and Analysis Function

The robot is equipped with an infrared thermal imager to obtain the infrared thermal images of the detected equipment in real time, store and analyze the heating situation of the detected equipment, and give early warnings of abnormal equipment temperatures.

Data Query Function

The real-time status, historical records, abnormal records and other information of the robot's inspection can be queried through the upper computer.

Navigation and Positioning Function

The unique navigation and positioning technology can make the robot's positioning and alarm more accurate.

A certain chemical plant

On site application in a coal mine factory

Refinery

coking plant